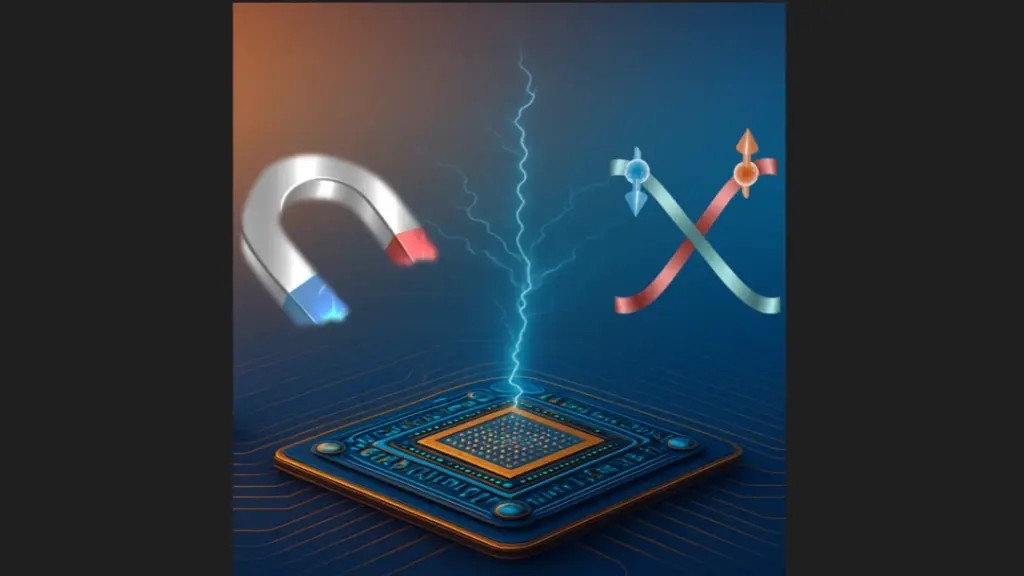

“These flat magnetic nanostructures present promising potential for advanced applications, including in-material computation, that is that the material itself can function as a computer, processing and calculating solutions internally, making certain types of problem-solving faster and more efficient”, says Christina Vantaraki, PhD student at the Department of Physics and Astronomy and the developer of the method.

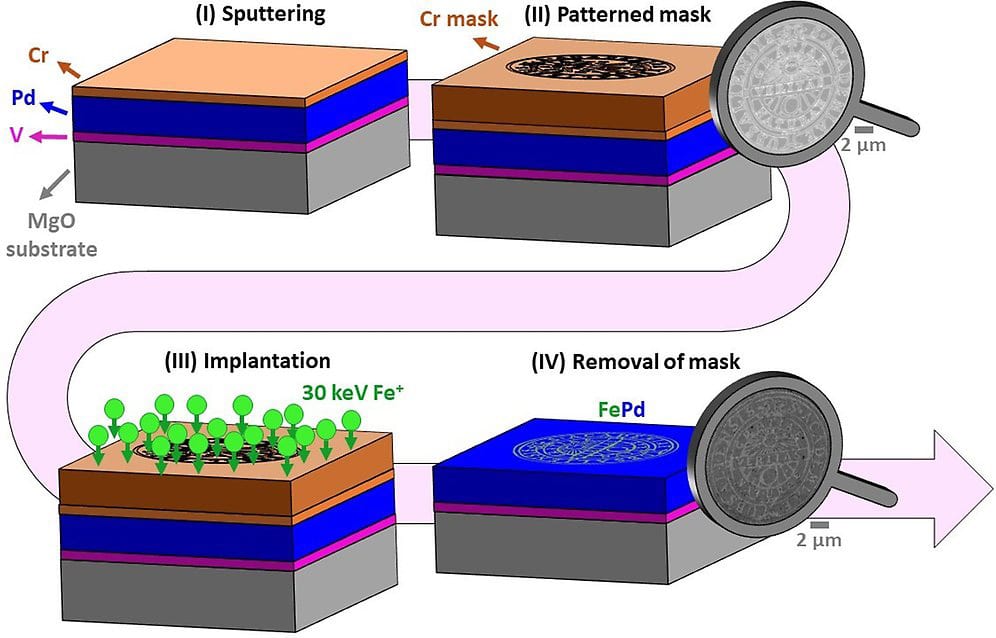

This new way of designing nano magnets was supported through resources at the Materials Physics Division of the Department of Physics and Astronomy, MyFab Uppsala, and the Tandem Laboratory and was achieved in four steps.