APR Technologies AB, based in Enköping, Sweden, is advancing its core pump technology through cutting-edge microfabrication – an essential yet resource-intensive process.

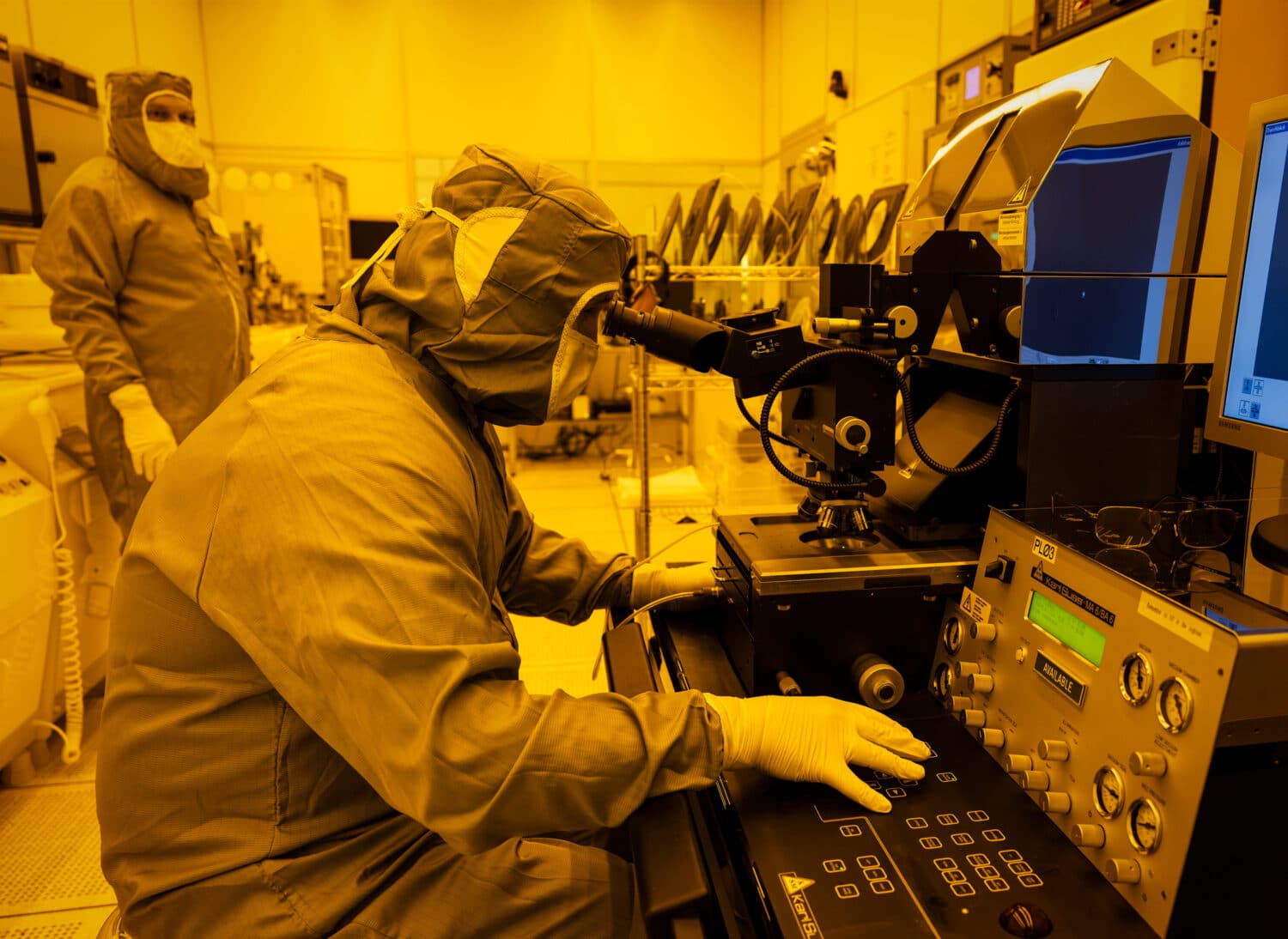

As the technology is still undergoing development and verification, the company has opted against investing in dedicated fabrication facilities at this stage. Instead, APR leverages access to Myfab. This provides APR with a professionally maintained environment that includes advanced equipment, chemical handling protocols, high cleanliness standards, and specialized processes such as lithography.

“This collaboration allows us to focus our resources on innovation and product development, without the overhead of building and maintaining our own fabrication labs,” says Peter Nilsson (CEO). “It enables us to accelerate R&D, ensure process reliability, and maintain flexibility as our technology matures.”

APR Technologies specializes in advanced thermal management solutions for space and ground-based electronics and battery systems. Their compact, low-power, and vibration-free products use dielectric fluids and electrohydrodynamic (EHD) pumping technology. The company’s portfolio includes both passive and active systems – such as thermal switches, heat exchangers, and fluid loops—designed to optimize performance in demanding applications across space, ICT, and battery sectors.