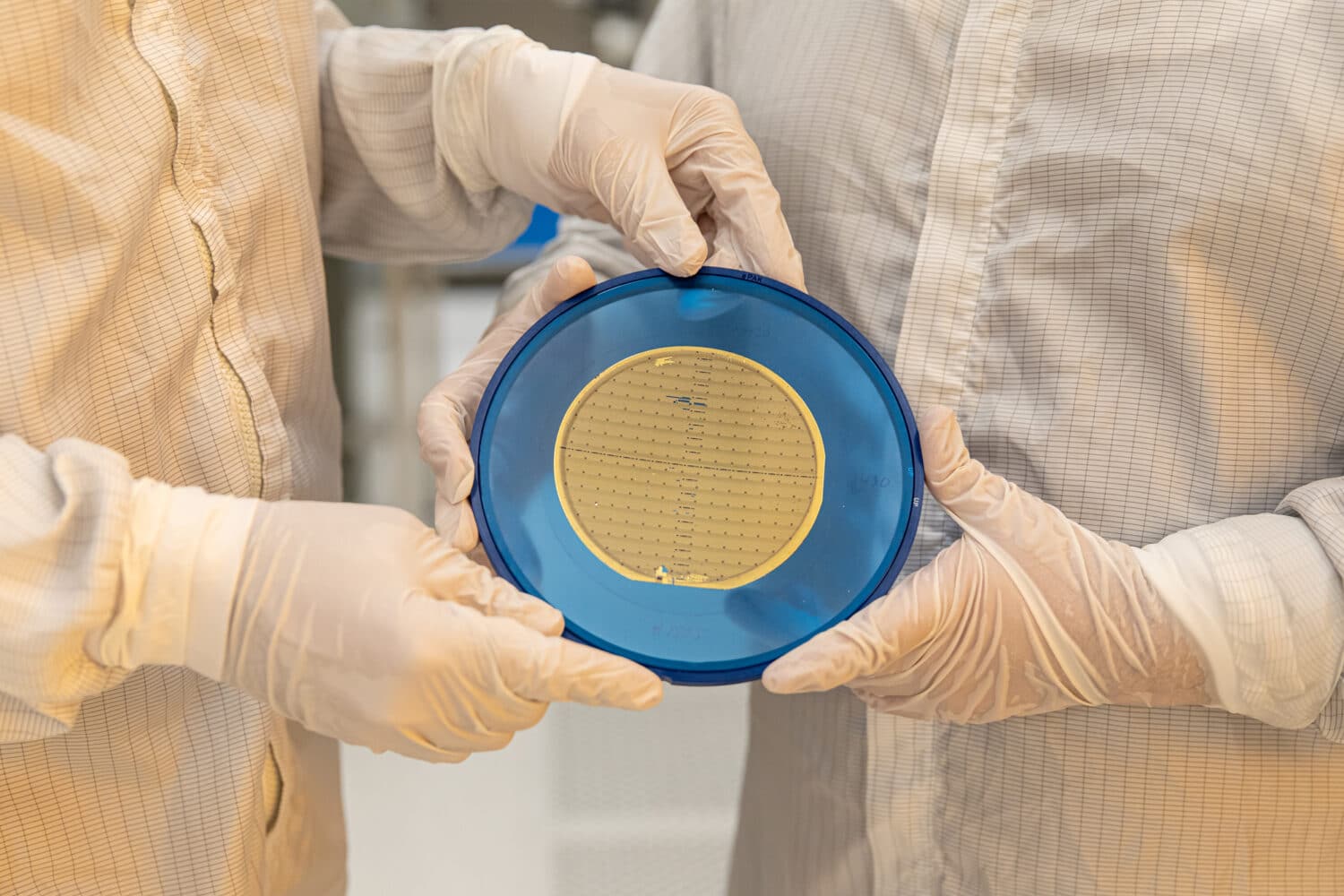

Low Noise Factory, a spin-off from Chalmers and Caltech founded in 2005. Their transistor technology requires advanced microfabrication, which is why access to cleanroom is essential. It enables fast iteration, process refinement, and innovation – without the cost of building their own facility.

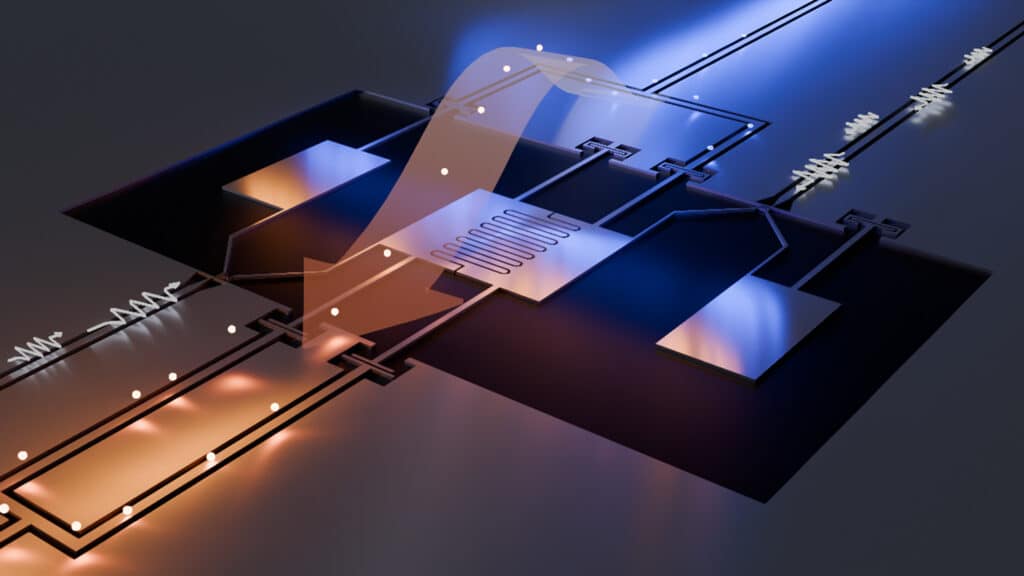

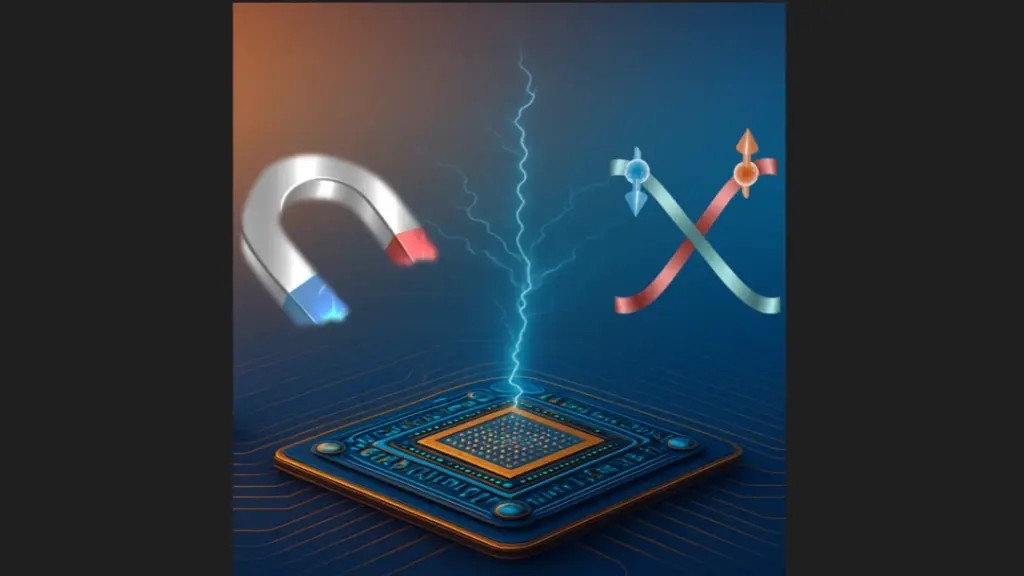

Low Noise Factory (LNF) develops cryogenic microwave amplifiers that operate at extremely low temperatures. These amplifiers boost faint signals used in space research, quantum computing, and radio astronomy, and are key components in many advanced scientific experiments.

Using Myfab’s cleanroom at Chalmers provides access to a world-class environment equipped with the latest semiconductor processing tools. It also offers valuable collaboration with experienced cleanroom staff who have strong backgrounds in research and process development.

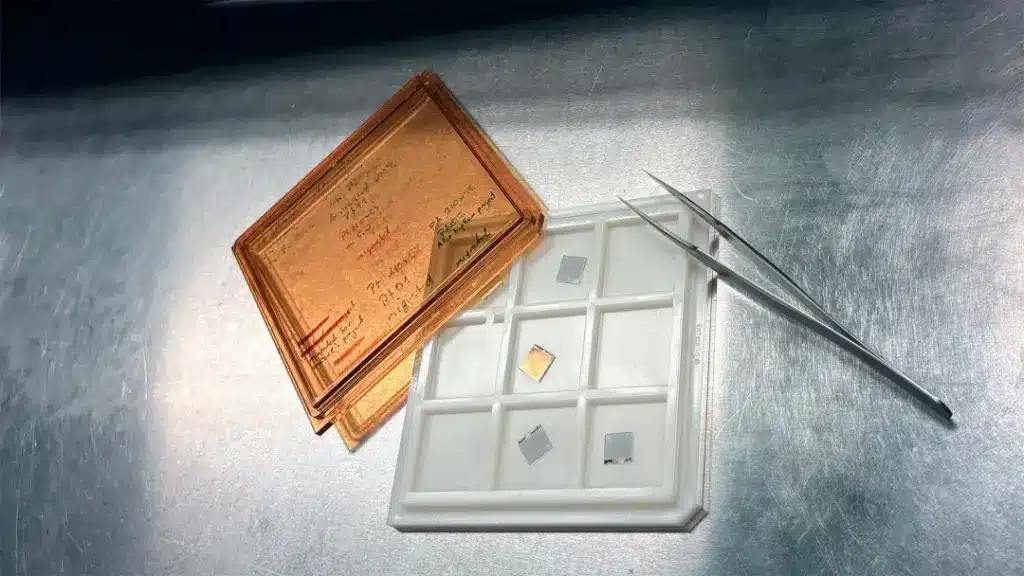

“Our transistors are produced using electron beam and laser lithography. Precision is measured in nanometers and single layers of atoms – this level of accuracy defines the quality of our amplifiers,” says Arsalan Pourkabirian, Head of Semiconductor Devices at Low Noise Factory.

This access allows LNF to fine-tune every step of its transistor fabrication process and iterate quickly. By leveraging this unique opportunity, the company has successfully maintained a competitive edge in the industry.