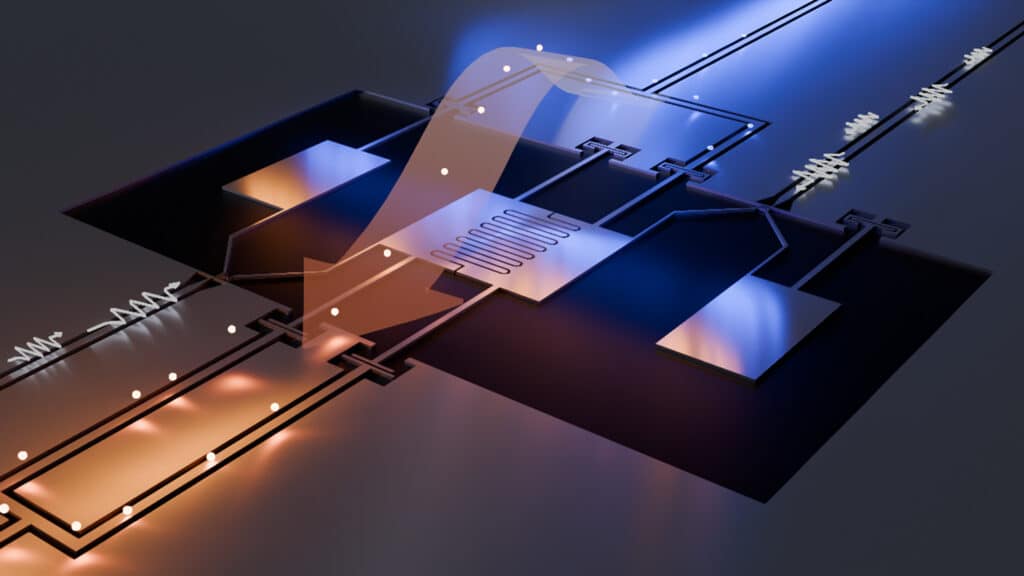

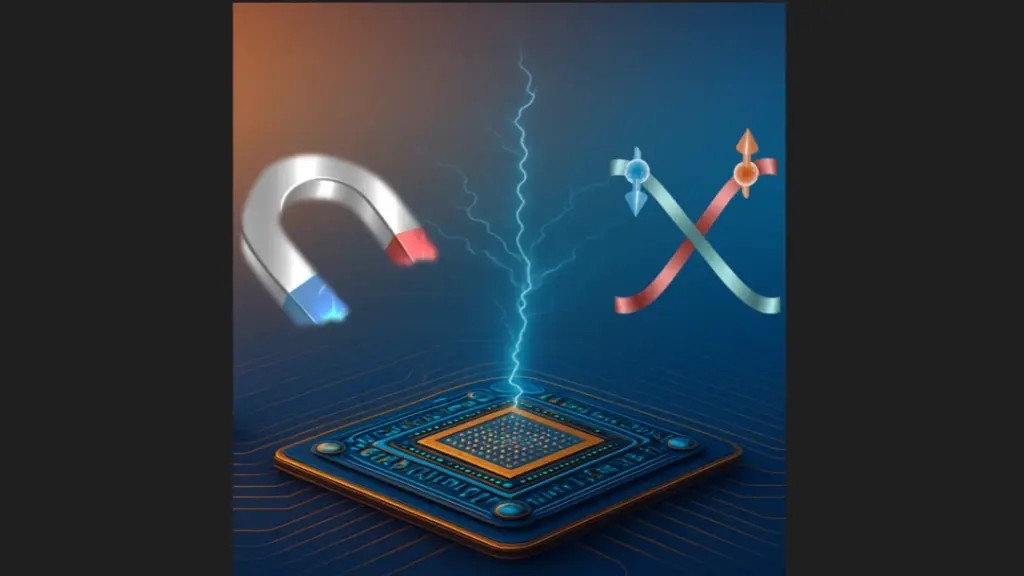

What started as a discovery in Myfab Lund/ Lund Nano Lab ten years ago is now turning into a sustainable path for the semiconductor industry. AlixLabs recently closed a €14.1 million Series A funding round, and aims to build a new generation of semiconductor manufacturing solutions, using the Atomic Layer Etching Pitch Splitting (APS™) technology enables more cost-effective, leading-edge chip manufacturing.

AlixLabs scales up with €14M investment

Beta testing underway and manufacturing planned by 2027. Lund University and NanoLund spin-out company AlixLab’s disruptive technology for miniaturising electronic chip fabrication is becoming big.