Sarah McKibbin, process and tool responsible research engineer at Lund Nano Lab, receives support from the Lund University Sustainability Fund for the “Greening Lund Nano Lab” project.

During the winter, the fund opened a call for proposals to test solutions to sustainability challenges in the organisation. Lund University is deeply committed to its strategy and plan concerning sustainability, aiming for remarkable achievements in this area. We know that change requires new ideas. That’s why the staff at Lund University have the opportunity to seek funding to address real sustainability challenges within the organisation itself.

The project “Greening Lund Nano Lab”

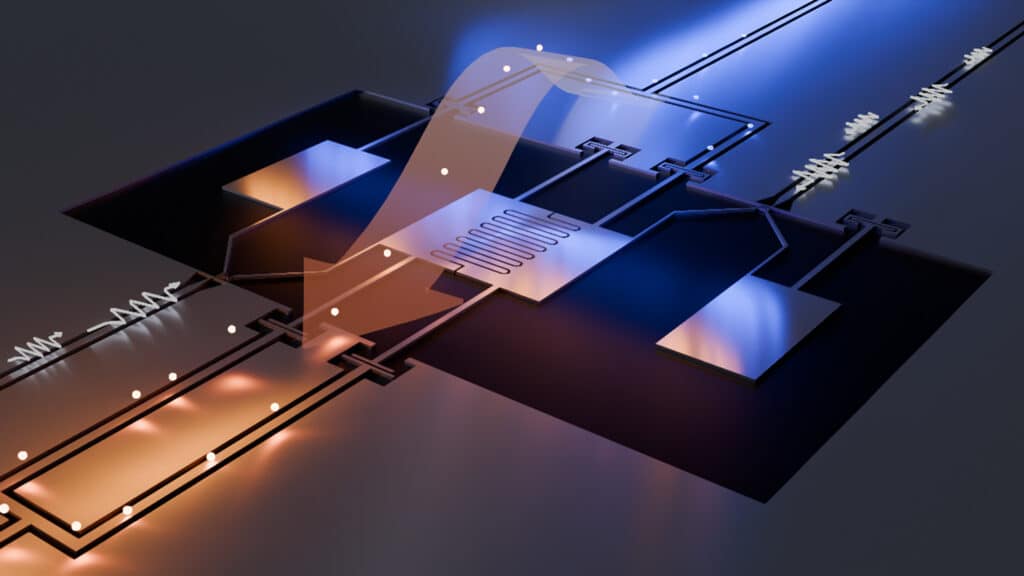

Laboratories are some of the most energy-intensive workplaces on the planet. In particular, cleanrooms and nanofabrication labs have some of the highest needs for energy consumption due to the need for climate control (temperature, humidity, and particles) that affect ventilation demands; heating, ventilation, and air conditioning (HVAC) power requirements for processing equipment; and the waste generation and chemical consumption that is associated with the work that is done.

Some steps have been taken at the Lund Nano Lab to reduce the overall energy consumption by, for instance, reduction of airflow at off-peak times, but significant investment would be needed to implement waste heat recovery. Achievable targeted topics to improve upon at Lund Nano Lab include optimising lab routines, minimizing unnecessary consumption of lab consumables (or recycling where possible) and improving user behavior. Several internationally recognized initiatives exist with which to evaluate lab practices and the sustainability of lab operation and practices. This project proposes that Lund Nano Lab evaluates and participates in the best of these options to improve the sustainability of the lab.

This project is one of six projects receiving support of up to 300,000 SEK each, for a project period of up to 12 months.

Original Article: https://www.nano.lu.se/article/sarah-mckibbin-gets-funding-greening-lund-nano-lab