Obducat benefits from the infrastructure at Myfab Lund/ Lund Nano Lab through the access to advanced tools beyond its own cleanroom. This collaborative approach strengthens development and supports innovation in healthcare, energy, and communication.

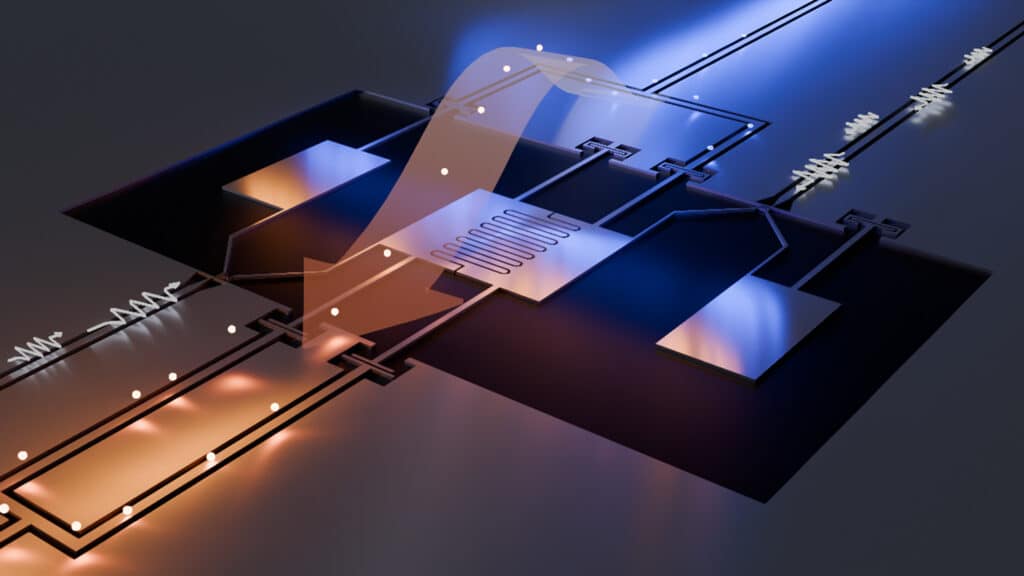

Obducat is a Swedish high-tech company founded in 1989, specializing in micro- and nanolithography solutions. With around 46 employees and over 140 patents, Obducat offers advanced equipment and foundry services based on Nanoimprint Lithography (NIL). The technologies support innovation in optics, photonics, sensors, and medical devices, serving both research and industrial production worldwide.

“In today’s rapidly evolving technological landscape, access to world-class research infrastructure and expert support is of complementary benefit to our own facilities and capabilities. It helps us drive innovation, enables solutions to global challenges, and contributes to advancements in healthcare, energy, and communication,” says Yi Liu, Team Leader and Senior Process engineer, Obducat.

Access to the cleanroom facilities at Myfab Lund/ Lund Nano Lab, plays an important role in adding to Obducat’s development capabilities. The lab offers a broad spectrum of advanced processing technologies that extend beyond the scope of Obducat’s own cleanroom, enabling the company to carry out complex micro- and nanofabrication tasks for its internal R&D activities that would otherwise be out of reach.

This collaboration not only strengthens Obducat’s technical capacity but also fosters valuable interaction with the academic community at Lund University, creating opportunities for knowledge exchange.

The expertise of the dedicated tool and process specialists is a key asset. Their hands-on support and deep technical know-how contribute significantly to the success of development projects, helping accelerate progress and ensure high-quality outcomes.